| St Rollox Chemical Works | |

|---|---|

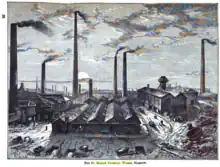

St Rollox Chemical Works 1884 | |

St Rollox Chemical Works | |

| Built | 1797 |

| Location | 229-231 Castle Street, Glasgow |

| Coordinates | 55°52′25″N 4°13′57″W / 55.8735°N 4.2324°W |

| Industry | Chemical industry |

| Products | Bleach, Sulphuric Acid, Soap, soda, Sulphur, Manganese |

| Area | 130 acres |

| Owner(s) | Charles Tennant |

| Defunct | 1964 |

St Rollox Chemical Works was a industrial manufacturer of chemicals[1] located in Glasgow, Scotland, that began in the Georgian era in 1799 and operated continuously until 1964. It was owned and operated by Scottish industrialist Charles Tennant[2] and was described as the largest plant in Europe, if not the world.[3]

Formation

In 1787, Tennant attended a demonstration of the Claude Louis Berthollet’s chlorine bleaching process that was held by Watt in Birmingham.[4] Tennant took the bleaching process and adapted it by substituting lime instead of potash by solving the problem of lime's inability to form a solution in water.[4] He received a patent No. 2209 on 23 January 1798 for the manufacture of a bleaching liquor by passing chlorine into a well-agitated mixture of lime and water that produced a strong bleaching liquor.[5]

The new process reduced both the cost of the bleaching liquor and reduced the damage caused by the liquor to the cloth.[4] However the new liquid had a short shelf-life, so Tennant and Macintosh decided to licence there new process and toured Lancashire manufacturers to sell the process for £200 each.[6] In the beginning the scheme worked relatively well with each bleach manufacturer reporting they were saving between £1000-£2500 per year.[6] However, the process began to more widely known and number of Lancashire manufacturers decided to use it with obtaining a licence from Tennant.[6] He decided to sue for infringement of patent rights but lost in court.[6] Tennant took the case to the Crown Court in 1802 but lost again.[6] However, in the intervening period, Tennant came up with a new process, that was granted a patent No. 2312 on 30 April 1799[7] for a new bleaching powder (calcium hypochlorite). At the time Tennant decided to open a new factory to commercially develop the product.[8]

In 1799, Tennant with three business partners, created the legal entity. The first of these, Dr. William Couper, was the legal advisor to the partnership. The second partner was Alexander Dunlop (His brother married Charles' eldest daughter), who served as accountant to the group. The third partner, James Knox, managed the sales department. The chemist Charles Macintosh was the fourth partner.[9] It was decided to locate the new factory at St Rollox in North Glasgow close the Monkland Canal that enabled it to transport coal and ironstone from the coal mines in Lanarkshire.[3]

Operation

St Rollox was started as a chlorine bleaching manufacturer that used Claude Louis Berthollet potash-chlorine bleaching liquor, that was modified by substituting the potash with lime to produce a bleach.[3] In 1799, the process changed when the company moved to the Macintosh-Tennant process to produce dry bleaching powder[3][10][11] The powder was made from chlorine and slaked lime that became known as Tennants bleaching salt.[12] It was produced by mixing 4 parts of water, 4 1/2 parts salt, 2 parts of manganese and 4 parts of sulphuric acid known as "Vitriol" in a leaden vessel heated in water bath.[12] The powder proved to be popular and sold well and this enabled the factory to expand and diversify internally.[3] At the time, sulphuric acid cost £60 per ton and large quantaties were needed in the production of chlorine, so Tennant decided to start producing it.[3][12] By 1802 the factory was producing 252,270lbs of vitriol per year and selling 151,117lbs of bleaching powder per year, valued at £7500.[12]

In 1803, St Rollox had installed six lead vessels to produce the bleach, measuring 10 x 12 feet by 10 feet high[13] In 1803, the house that contained the vessels was of three floors about 50 foot long by 24 feet, the upper floor contained the vessels, the floor below the glass retorts for concentrating acid and the bottom floor contained the lead evaporating boilers used to bring the acid up to strength for the glass retorts.[13] In 1807, a further eight more were added.[12] By 1809, production capacity had been increased further, with 26 vessels in total.[12] This was further increased by six in 1811, taking the total number to 32 and were much larger, measuring 60 x 14 x 12feet high, arranged in sets of two or three.[13] The chambers were constructed to use external furnaces that burnt the sulphur and supplied gas by use of a flue.[12] These were supplied by Bealy and Radcliffe of Manchester.[12][14]

When the Salt tax was removed, the factory moved to producing crystal and ash soda using the Leblanc process in the 1820's.[3] The process to create alkali's was to add sulphuric acid to salt that produced sodium sulphate which was known as saltcake. The cake was roasted in a vessel by furnace and lime and coal to produce sodium carbonate (soda ash) that was immersed in water for 12 hours. The resultant liquid was put into lead pans to evaporate.[14] This enabled the factory to expand further with the use of platina lined vats to hold the vitriol concentrates instead of the less efficient lead lined, more furnaces, more warehouses and storage space as well as building a canal basis and a railyway terminal.[3] By 1850, further expansion had added a cooperage and an iron foundry to make and repair their own equipment.[3]

In 1871, James MacTear, who was the manager at St Rollox, created a chemical process to recover sulphur from the waste piles behind the factory.[15] It involved pumping the waste liquor from the soda heaps into a special vessel, treating it with sulfurous acid to form an oxide, that was then dissolved with water, then hot hydrochloric acid was used to precipitate the sulphur, that was then dried and fused.[15] The process was reliable, resulting in product that was cheap to produce and was widely used by manufactures, even though it recovered only 27% to 30% of the available sulphur.[15] 1 ton of sulphur could be recovered at a cost of 61shillings at a cost of £2000 for an apparatus, that could produce 35 tons per week and plant itself could produce 100 tons per month.[16] The sulphur was considered of excellent purity and was generally used to make gunpowder.[16]

Pollution

References

Citations

- ↑ Bertram 1884, p. 296.

- ↑ Hutchinson 2023, p. 351.

- 1 2 3 4 5 6 7 8 9 Christie 2018, p. 313.

- 1 2 3 Chang & Jackson 2007, p. 172.

- ↑ Harden 1898, p. 60.

- 1 2 3 4 5 Chang & Jackson 2007, p. 173.

- ↑ Chisholm 1911.

- ↑ Chang & Jackson 2007, p. 174.

- ↑ Alison 1892, p. 343.

- ↑ Macintosh, George (1847). Biographical Memoir of the Late Charles Macintosh ... Glasgow: W.G. Blackie & Company. p. 38.

- ↑ The Repertory of Arts, Manufactures, and Agriculture: Consisting of Original Communications, Specifications of Patent Inventions, Practical and Interesting Papers, Selected from the Philosophical Transactions and Scientific Journals of All Nations ... Vol. XI. London: G. and T. Wilkie. 1799. p. 72.

- 1 2 3 4 5 6 7 8 Bertram 1884, p. 298.

- 1 2 3 Crookes et al. 1877, p. 16.

- 1 2 Timmins 1998, p. 114.

- 1 2 3 Reed 2016, p. 148.

- 1 2 Bertram 1884, p. 300.

- ↑ Anderson, Thomas (August 1865). Report on the refuse matters of the St. Rollox works, and their effect on the water of the River Clyde (Report). Glasgow: R Anderson, University of Glasgow.

Bibliography

- Chisholm, Hugh, ed. (1911). . Encyclopædia Britannica. Vol. 26 (11th ed.). Cambridge University Press.

- Alison, Robert (1892). "The Tennants of St. Rollux". The anecdotage of Glasgow. Glasgow: Thomas D. Morrison.

- Bertram, James G (1884). "Model Establishments - V. The St Rollox Chemical Works, Glasgow". Great industries of Great Britain. Vol. 1. London: Cassell, Petter, Galpin and Company. pp. 296–300.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain. - Crookes, William; Gardiner, James H.; Druce, Gerald; Ryan, H. W. Blood (1877). "Chemical News and Journal of Physical Science". XXXV. Chemical news office: 16.

{{cite journal}}: Cite journal requires|journal=(help) This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain. - Christie, John R.R. (2018). "Chemical Glasgow and its Entrepreneurs, 1760-1860". In Roberts, Lissa; Werrett, Simon (eds.). Compound Histories Materials, Governance and Production, 1760-1840. Cultural Dynamics of Science. Vol. 2. London: 978-90-04-32549-4. pp. 311–332. doi:10.1163/9789004325562_015.

- Chang, Hasok; Jackson, Catherine (2007). An element of controversy: the life of chlorine in science, medicine, technology and war. London: British society for the history of science. pp. 168–174. ISBN 978-0-906450-01-7.

- Harden, Arthur (1898). "Tennant, Charles". In Stephen, Leslie; Lee, Sidney (eds.). Dictionary of National Biography Teach to Tollet. Vol. 56. London: Smith, Elder and Co.

- Hutchinson, Martin (1 January 2023). Forging Modernity. Cambridge, uk: Lutterworth Press. ISBN 978-0-7188-9686-7.

- Reed, Peter (23 March 2016). Acid Rain and the Rise of the Environmental Chemist in Nineteenth-Century Britain: The Life and Work of Robert Angus Smith. Science, technology, and culture, 1700-1945 (1st ed.). London: Routledge. p. 148. ISBN 978-1-317-18582-6.

- Timmins, Geoffrey (15 December 1998). Made in Lancashire: A History of Regional Industrialisation. Manchester: Manchester University Press. ISBN 978-0-7190-4539-4.