Introduction

Over time, the Brother SC 9500 computerized sewing machine begins to make a high-pitched metallic squeak when the needle rises and falls. The sound is usually the combination of two issues: 1) dust build up in the feed dogs and bobbin well; and 2) a dry joint in the needle arm mechanism that requires oiling. Addressing these two problems stops the squeaking. Let's begin!

Tools

-

-

Flip the power switch on the back end of the sewing machine to "off."

-

For extra security, also unplug the power cord entirely.

-

-

-

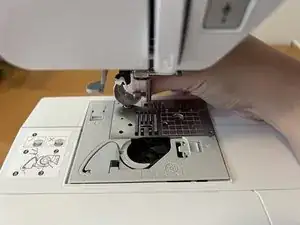

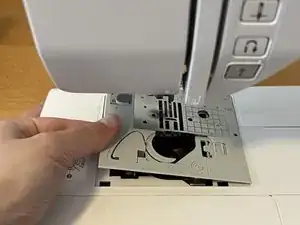

Slide the bobbin plate lock switch to the right.

-

Remove the plate cover.

-

Remove the bobbin (if you have one loaded).

-

-

-

Locate the presser foot release switch on the back of the presser foot.

-

Squeeze the release switch gently.

-

-

-

Use a coin to twist the needle securing screw towards yourself (counterclockwise).

-

The needle will drop down when it's loose enough. Carefully set the needle aside.

-

-

-

Use a coin to unscrew the two screws holding the bobbin well cover plate in place.

-

Lift the well cover plate from the left edge first to remove it.

-

-

-

Use a straw cleaner to remove dust and lint from the bobbin well tray.

-

You should also use the straw cleaner to clean between the metal teeth on the feed dogs.

-

-

-

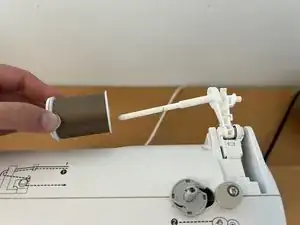

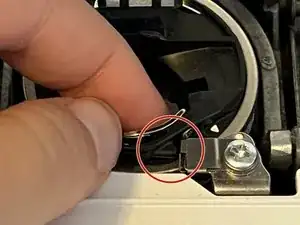

Replace the bobbin well once all the dust is gone.

-

Make sure the black tab on the black bobbin well is placed right up against the metal spring in the bobbin well tray.

-

-

-

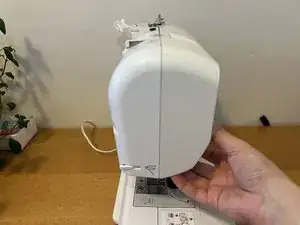

Turn the machine around to the back and unscrew the single screw on the far right edge.

-

Pinch the bottom edge of the faceplate and pull up to detach.

-

-

-

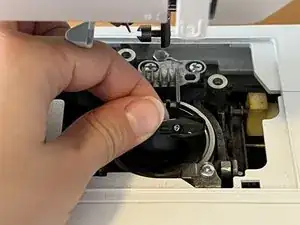

Use the straw cleaner to dust the top, bottom left, and inner right sides of the internal needle arm mechanism.

-

-

-

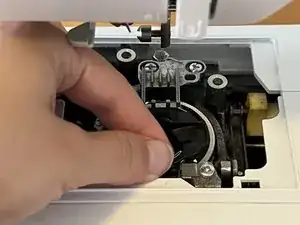

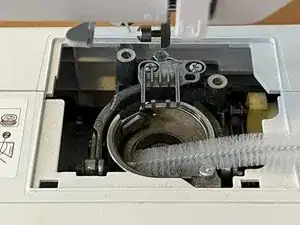

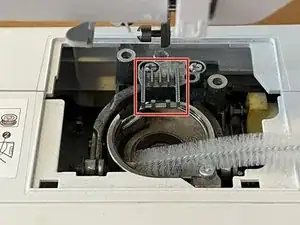

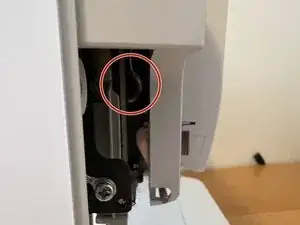

Locate the inner joint. It looks like a large round disk in the right side of the needle arm mechanism.

-

Apply two drops of sewing machine oil to this joint.

-

-

-

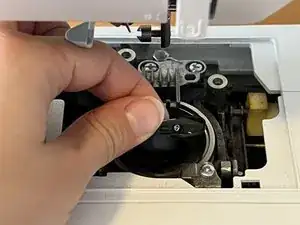

Turn the hand wheel on the end of your machine two full times clockwise to spread the oil around the joint.

-

-

-

Replace the faceplate.

-

Slot the top edge over the exposed inner mechanism first.

-

Lower the faceplate cover until it snaps into place at the bottom.

-

Replace the screw of the back of the machine until it is hand-tight.

-

-

-

Align the presser foot bar with the presser foot clip.

-

Pull down on the presser foot lever to push the clip into the bar. It will audibly snap into place.

-

Push the presser foot lever up to check that the presser foot is secure.

-

-

-

Lastly, carefully replace the needle.

-

Sewing machine needles have a round front and a flat back. Insert the needle with the flat back facing away from you.

-

Use a coin to tighten the needle screw clockwise until it is hand-tight.

-

Congratulations! Your sewing machine is ready to be re-threaded and used. Enjoy sewing squeak-free.